Notes and Precaution

NOTE 1

What are some precautions when installing power supplies in the end system?

The AC power line shall be turned off, and live wire connections shall not be exercised. Turn on AC power after all connections have been properly made to avoid the electrical hazard.

The AC power line shall be turned off, and live wire connections shall not be exercised. Turn on AC power after all connections have been properly made to avoid the electrical hazard.

It is recommended to install the power supply horizontally per datasheet. If there are space limitations and power supply cannot be installed horizontally, please de-rate the power supply output as necessary and keep the ventilation holes unobstructed to ensure proper ventilation affecting power supply lifetime.

It is recommended to install the power supply horizontally per datasheet. If there are space limitations and power supply cannot be installed horizontally, please de-rate the power supply output as necessary and keep the ventilation holes unobstructed to ensure proper ventilation affecting power supply lifetime.

Pay attention to the maximum length of mounting screws as specified in the datasheet. If the length exceeds the specifications, the screw may come in contact with internal components and cause electrical failures or even endangerment. Please refer to the installation manual for the appropriate torque settings and wire gauge.

Pay attention to the maximum length of mounting screws as specified in the datasheet. If the length exceeds the specifications, the screw may come in contact with internal components and cause electrical failures or even endangerment. Please refer to the installation manual for the appropriate torque settings and wire gauge.

When the system is Class I installation, connect the power supply frame ground (FG) with the system frame ground (FG). For more details on installation precautions, please visit Selection Guide-Installation Manual and download the corresponding installation manuals per product types.

When the system is Class I installation, connect the power supply frame ground (FG) with the system frame ground (FG). For more details on installation precautions, please visit Selection Guide-Installation Manual and download the corresponding installation manuals per product types.

NOTE 2

Cooling methods for power supplies

As specified in the MEAN WELL datasheets, power supplies typically have 3 different types of cooling methods: free air convection, built-in fan cooling, and external fan cooling. The installation of the external fan needs to be considered in the end system. If there is no external fans added, output power needs to be de-rated according to the datasheets.

NOTE 3

EMC debugging suggestions for end systems with integrated power supplies

MEAN WELL power supplies comply to EMC requirements by themselves, but since power supplies are components, the EMC performance of the end system my not be compliant and needs to be evaluated as a whole. When there are EMC related issues, you may try the suggestions below:

1 Add EMI filter to the power supply input

2 Add grounding choke

3 Add EMI cores to the AC or DC cables

NOTE 4

Leakage current considerations

Medical products have very stringent requirements for leakage currents, and MEAN WELL medical power supplies are designed to meet the safety requirement levels. However, the system level leakage current will increase when there are multiple power supplies in the system, thus when the end system needs to utilize multiple output voltages or power supplies, it is highly recommended to use medical grade modular power supplies, such as the NMP series, in order to ensure the leakage current requirements are met.

NOTE 5

System requirements for applied parts (Type B, BF, or CF)

Power supplies are not medical equipment nor applied parts, and the power supplies shall not come in direct contact with the patients. Most medical equipment has medical grade power supplies, but only the parts of the equipment that comes into contact with the patients are classified as applied parts.

Applied parts for medical systems can be classified into Type B, BF, or CF:

| Type | Protection Level | Explanation | Equipment Example |

| Type B | Least strict | Does not come in contact with the patient during normal use and can be immediately removed if come in contact with the patient. | Respiratory equipment |

| Type BF | strict | Comes in contact with the patient during normal use, but does not touch the heart of the patient | ECG |

| Type CF | Most strict | Can come in contact with the patient heart during normal use | pacemaker |

Type B applied part can be grounded, but Type BF and CF applied parts must be “floating” and isolated from the ground. Depending on the applications and requirements of the end system, an appropriate power supplies and isolation shall be considered to ensure meeting the safety requirements for medical systems.

NOTE 6

What is class 2, class II and LPS? What is the difference between class I and class II?

Class I: Equipment where protection against electric shock is achieved by using basic insulation and also providing a means of connecting to the protective earth conductor in the building whereby routing those conductive parts that are otherwise capable of assuming hazardous voltages to earth ground if the basic insulation fails. This means a class I SPS will provide a terminal/pin for earth ground connection.

Class II: Equipment in which protection against electric shock does not rely on basic insulation only, but in which additional safety precautions, such as double insulation or reinforced insulation are provided, there is no reliance on either protective earth or installation conditions. This means a class II SPS does NOT have a terminal/pin for earth ground connection.

The decision on whether to use Class I or Class II power supplies is typically dictated by the end system. If the end system is Class I type, please select Class I power supply, and if the end system is Class II type, please select Class II power supply to avoid performance issues with EMI, hi-pot, etc.

NOTE 7

End system requirements for power supplies with MOOP or MOPP rating

a. MOOP: provide adequate protection to the operator

b. MOPP: provide adequate protection to the patient

c. MOP: only one protection

The end system needs to utilize power supplies with the appropriate ratings to ensure safety for the patients or operators.

NOTE 8

Protection features of power supplies

When current drawn exceeds the rated output current of the power supply, the protection circuit will be triggered to protect the power supply against overload/overcurrent.

Protections of overload/overcurrent can be divided into several forms:

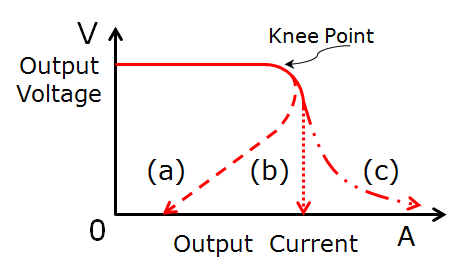

(1)FOLDBACK CURRENT LIMITING

Output current decreases about 20% of rated current, shown as curve (a) in the figure below.

(2)CONSTANT CURRENT LIMITING

Output current remains at a constant level and within the specified range while the output voltage drops to a lower level, shown as curve (b) in the figure below.

(3)OVER POWER LIMITING

Output power remains constant. As output load increases, the output voltage decreases in proportion, shown as curve (c) in the figure below.

(4)HICCUP CURRENT LIMITING

Output voltage and current keep pulsing ON and OFF repeatedly when protection is activated. The unit automatically recovers when faulty condition is removed.

(5)SHUT OFF

Output voltage and current are cut off when the output load reaches the protection range.

NOTE: Protection mode of some of the products combines with different types of forms mentioned, such as constant current limiting + shut down.

Recover method:

(1)Auto Recovery: PSU recovers automatically after fault condition is removed.

(2)Re-power on: PSU restarts by manual AC re-power on after fault condition is removed.

Note:Please do not operate PSU in overcurrent or short-circuit condition for a long period of time to prevent a shorten lifespan or damaging the PSU.